This is how we do it, do it

The life of a sock design is very intriguing. Most people don’t realize that it can often take a full 90 days to bring the concept to the shelf. It may be long, but we feel it is the only way we can add our stamp of approval, with quality one of our utmost priorities. After all, we want you to love the socks you wear, and be proud of what you stand upon, from fit to finish.

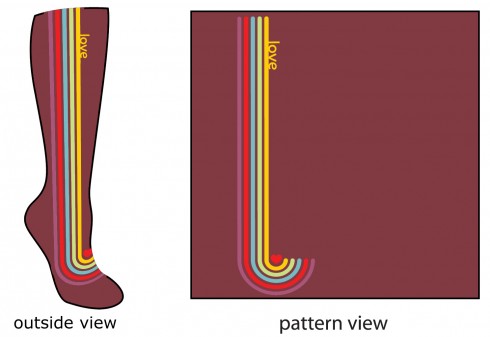

Thinking the process is pretty interesting stuff, we thought you’d enjoy taking in the general timeline… which begins with a design, like the Grand Prize winning “Love Luma” submitted in last year’s Global Design-A-Sock Contest:

As we look at producing the sock, we have to first decide if we need to make any adjustments to the design to accommodate the thread alignment and how it could affect stretch and quality. Sometimes they are fine as they are; if not, we hire a designer to recreate the design for us (explaining why we ask for simple designs and limit colors used in our design contest).

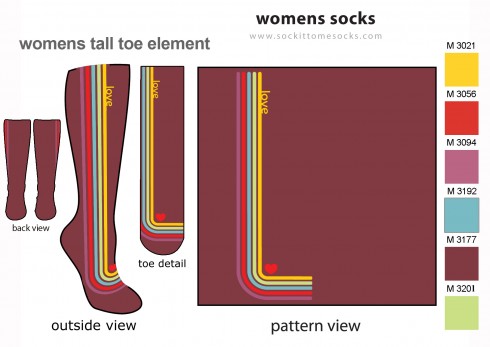

We then decide if we want to alter or keep the colors to fit our style. Using the color book given to us by our manufacturer, we nail down the final colors and plug it all into a template for the factory, with the colors notated on the side like this:

At that point, we send the design to our factory in Korea, with 10-30 other designs we’ve prepared simultaneously. Once produced, the first run samples are express mailed back to us. We get the crew together and try them on all of our varying leg sizes to evaluate fit and find design malfunctions, paying specific attention to how they stretch and how the designs pull.

In this case, we noticed the “love” lettering needed thickening and the stripes needed extending, since they stopped mid-foot, as you can see here:

If the design needs to be altered, we contact the designer to make those changes, or we note our revisions if they are easy (pictured below), and then we send the designs back to our manufacturer for another round.

Frequently, we nail down all of the kinks in that first round. But sometimes we have to send for another round or two of revisions to get it right. If it gets too complex, we have to decide whether or not we should drop the design altogether. It is always sad when that happens, since we’ve generally put a lot into the design by then. But quality is our main concern, so we try not to get attached until we are confident our customers will love the style and the fit.

Once we have perfected all of the designs, we get final samples sent as an express shipment and hand them off to our photographers to get shot in studio. After all, we want to be ready to publish the goods on our website as soon as they are in-house! While we have the finals in hand, we can also prepare for our catalog and other print materials with a photo shoot, like we did with the Love Luma, below.

Then FINALLY — after a 12-day journey by boat — our massive order (with 60-120 thousand pairs of socks) arrives from Korea at the Port of Portland, gets packed onto large containers and shipped to our door. We unpack the containers, stock our shelves, and get ready to sell to our customers and friends, who then display them in a pretty fashion, like Little Things in PDX (pictured below). If you look closely, you can see the Love Luma in the bottom right:

Just think. All of this, thanks to creative minds like design duo Luciana Mazzocco & Maxine Stinton who submitted their “Love Luma” design on a whim to win our annual design contest. And they did win! Your design could be next, you know. 🙂

Fun to see the process. So how long does it take you from the first time you send the design to the factory until the final order shows up at your door. What is the biggest thing you have learned through trial and error?

It usually takes about 90 days. We just submitted our order for Fall yesterday and we expect to get that order in July.