Jay’s Asia Trip

In addition to our liaison Sharon, who travels to our factories in South Korea all the time, we like to have a Sock It to Me employee go to Asia every other year to connect with our manufacturers and check in on operations. This year, Jay got to go!

Jay spent 10 days traveling, 5 in South Korea and 5 in China, to meet the folks he’s been conversing with via email for the last year. Jay is our Pre-Production and Quality Assurance expert. When new items come in, he’s the one who makes sure they meet our high standards. So, it made perfect sense that he should visit the factories where our socks and undies are made.

Jay’s first stop was Seoul, South Korea where our socks are manufactured. He was witness to the entire sock creation process from spools of thread on the wall to socks ready to head out the door.

Jay’s first stop was Seoul, South Korea where our socks are manufactured. He was witness to the entire sock creation process from spools of thread on the wall to socks ready to head out the door.

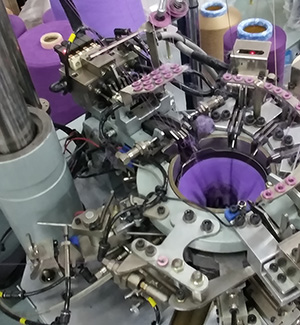

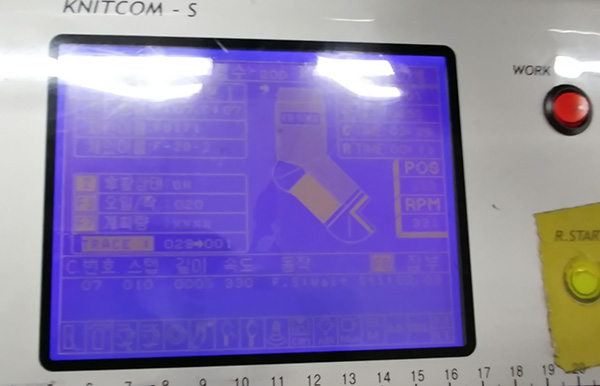

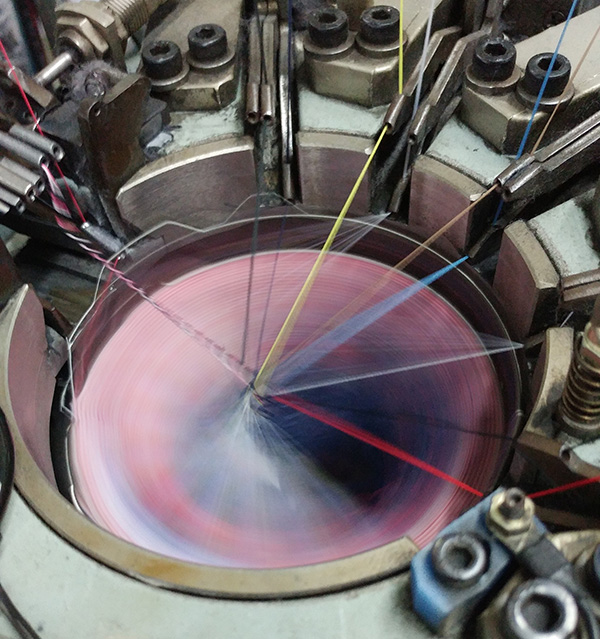

Hefty machines are programed with our designs and loaded with the appropriate color threads (you can see the purples and tan that go into our Sloth Sock being fed into this machine). The threads are spun back and forth until a sock tube is created.

The sock tube is spit out, inside-out and stacked on the machine. The pile of inside-out socks are taken to be turned right-side-out, one-by-one on wire frames. Once the socks have the proper side facing out, they get their toe seam added—an important step in differentiating the sock from a leg warmer.

The sock tube is spit out, inside-out and stacked on the machine. The pile of inside-out socks are taken to be turned right-side-out, one-by-one on wire frames. Once the socks have the proper side facing out, they get their toe seam added—an important step in differentiating the sock from a leg warmer.

After they become a complete sock, they are placed on the crazy-looking sock forms shown here to be boarded, steamed and flattened into the sock shape we know and love. After they have acquired their appropriate silhouette, our Sock It to Me tags are fastened to each pair and they are packaged to make their trip to the USA.

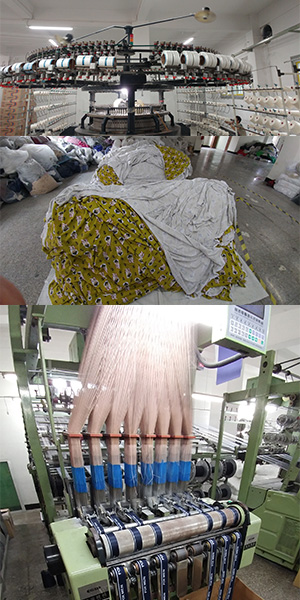

Next, Jay traveled to China. He got to watch a giant machine knit the fabric that gets turned into our underwear.

Thread is guided into the machine from multiple spools. The entire top of the machine is surrounded by tiny, circling fans. The fans serve two purposes: 1. They keep the machines cool, 2. They keep flying debris out of the fabric during the knitting process.

Thread is guided into the machine from multiple spools. The entire top of the machine is surrounded by tiny, circling fans. The fans serve two purposes: 1. They keep the machines cool, 2. They keep flying debris out of the fabric during the knitting process.

Once it is knit, the fabric is printed or dyed (we use an “all-over-roller-print for most of our designs) and laid out to rest so all creases and stretched portions become uniform before the cutting process. The prepared fabric is stacked up and cut into pieces that will get sewn into underwear. The elastic bands, though, are created on an entirely separate machine.

All of these machines are programed with our specific patterns to create our wacky designs and logo infused waist bands.

We have high standards across the board: for our products and for the people who produce them. Jay was also visiting these factories to ensure that they are meeting the expectations of the social compliance standards that we’ve established. We use third party auditors such as BSCI (Business Social Compliance Initiative) and Intertek: Workplace Conditions Assessment to set our expectations for compliance. These include:

Emergency Preparedness

No overtime without compensation

Freedom of association and collective bargaining

Occupational health and safety

And many more

Sock It to Me will continue to build relationships with our manufacturers, oversee what these factories are producing for us, and make sure they’re doing it in a socially compliant way.

Jay spent 3+ hours a day in a car traveling from facility to facility and only got one day off while he was there. He spent it with our liaison Sharon and David, the manager and son of the owner of the very first factory Sock It to Me started producing socks with. They went to Gyeongbokgung Palace and the National Folk Museum of Korea that lays within. Afterward, they went to the show Cookin’ Nanta which Jay describes as a cross between Stomp and Chopped. Cookin’ Nanta is the longest-running show in Korean history and has been staged in 18 countries around the world. We can’t wait for it to come back to America!

Jay spent 3+ hours a day in a car traveling from facility to facility and only got one day off while he was there. He spent it with our liaison Sharon and David, the manager and son of the owner of the very first factory Sock It to Me started producing socks with. They went to Gyeongbokgung Palace and the National Folk Museum of Korea that lays within. Afterward, they went to the show Cookin’ Nanta which Jay describes as a cross between Stomp and Chopped. Cookin’ Nanta is the longest-running show in Korean history and has been staged in 18 countries around the world. We can’t wait for it to come back to America!

They went out to some really amazing meals (like the sushi boat pictured), but Jay says his favorite was eating at the first factory he visited.

They have a kitchen where the chef makes different home-cooked style meals for their employees. They have a new menu every day, comprised of healthy food made with a lot of care. The owner of the factory eats there daily along with most factory employees from every level. Jay says it was such a communal, social, heart-warming experience, it makes sense that most people eat there every day.

Here are some more amazing behind-the-scene photos of Jay’s trip:

Hi,

I’ve bought a pair of your socks (the Sloth socks!) last year and absolutely love the design. I would like to purchase more, but would like to know more about the dyes and materials that you use to make your products. I appreciate the information you’ve provided on the social compliant standards your company is taking. I would like to know what kind of environmental compliant standards the factories where you manufacture your socks have put in place? And what other ethical standards are you working on? As a consumer, I would like to feel as good as the designs and socks that I’m wearing – knowing who made my socks and how they’re made will make me want to buy more sockittome products!

Thank you,

Nadiah

Hi Nadiah!

Great questions and thank you for your concern with what goes into the products you wear.

The threads in our socks, including the dyes, are OEKO-TEX® Standard 100 certified. You can read about that certification here: https://www.oeko-tex.com/en/business/certifications_and_services/ots_100/ots_100_start.xhtml

We also work with third party compliance systems BSCI and WCA to monitor the factories which produce our products to ensure they meet our standards. They address: management of chemicals, environmental performance, environmental management, occupational health and safety, social responsibility, and quality management. These are voluntary systems, which do not lead to certification, but instead help us regularly work with our suppliers to guarantee they meet a code of conduct.

I hope this answers your questions! If you have any more, please don’t hesitate to ask!

-SITM Team